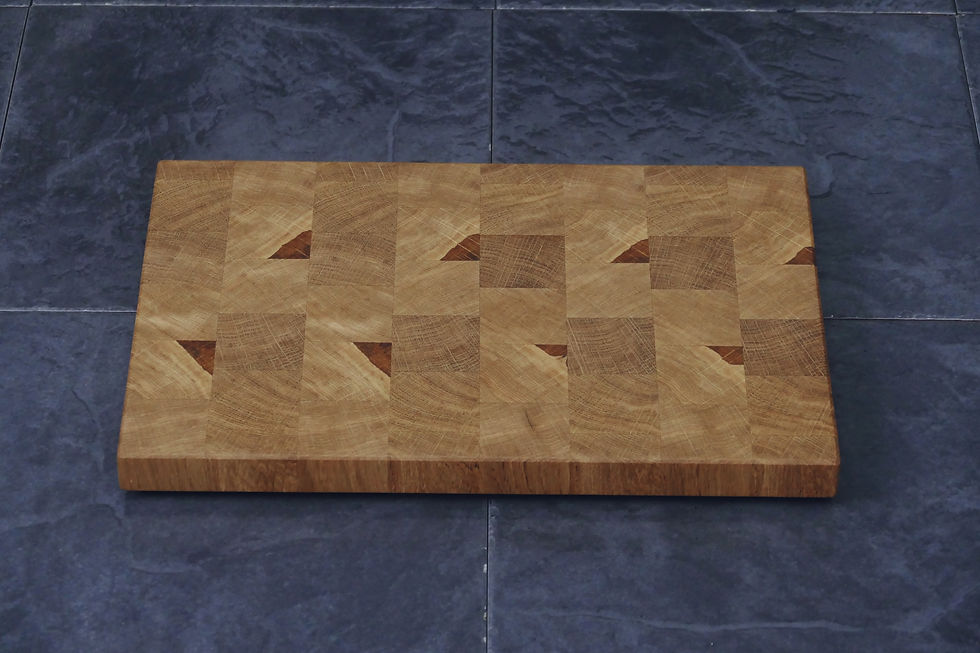

Why choose a Skinner Designs End Grain Chopping board?

Our End Grain Chopping Boards are made using high quality hand picked timbers, much of which are native species sourced from the UK. Incorporating these materials with our tried and tested techniques that have been developed over the past eight years, we are at the pinnacle of high end, handmade, End Grain Chopping Boards made in West Sussex.

Here is a comprehensive list of why a Skinner Designs End Grain Chopping board is the only choice.

Materials - Our Wood

We only source our timber from suppliers that can Guarantee FSC certified timber.

The Forest Stewardship Council – FSC is an independent, non-profit organisation

promoting responsible management of the world’s forests. Their certification system provides an internationally recognised standard-setting, and trademark assurance to

anyone, business or individual, who is interested in supporting responsible forestry.

All of our timber is hand selected by ourselves resulting in the best quality timber for our products.

Construction - Our Process

After hand selecting our timber, it is now onto hand making each board. A few noticeable points that differ from our competitors:

Each surface to be glued is sanded to 80 grit with no more than 12 hours before gluing. Sanding the wood prior to glueing gives multiple added benefits:

-

Glue adheres to fresh wood the strongest.

-

Sanding roughens up the wood increasing its microscopic surface area ten fold. This allows more surface for the glue to adhere to, resulting in a stronger joint.

-

Sanding creates an overall flatter surface than a planed surface meaning there is a greatly reduced potential of voids between the glued edge.

All glued joints are inspected for 'squeeze out'. This means that when a joint is clamped, some of the glue is squeezed out of it. This is how we know that sufficient glue has been applied. If this is not seen the joint is pulled apart and more glue added. It is important to see this squeeze out as the glue seals the wood together. Leaving it unsealed will result in the joint being able to absorb food/moisture in that area, with the potential to damage your board in the long run.

Self Healing

When a knife makes contact with the cutting surface it passes between wood fibres rather than cutting them. This prevents the wood from being noticeably damaged due to the resilient fibres coming back together to close around the cut.

Durable Surface

The end grain of the wood is up to three times harder than the face grain making it an ideal surface to cut on due to its durability.

_JPG.jpg)

Keeps Knives Sharp

As the knife edge slides between the wood fibres rather than cutting them it prevents excessive wear on your knives keeping them sharper for longer.

Easy to Clean

Cleaning your board is as simple as wiping down your cutting board with hot, soapy water then mopping up any excess water quickly. Finally, pat dry with clean paper towels and allow to air dry. We also recommend using an anti-bacterial spray when necessary.

Easy to Maintain - Wax & Oil

To maintain your end grain chopping board, all that is required is a monthly oil which is easy to apply. An additional step is to also wax the board which adds moisture repelling proprieties and gives your board it’s ‘new’ glossy look back.

Available to purchase is our own wax and oil to help maintain your chopping boards. These are made from food safe ingredients. Our oil is 100% pharmaceutical grade mineral oil. Our chopping board wax is made from a mix of natural filtered beeswax and mineral oil.

Stainless Steel Screws & Non Slip Levelling Feet

Our boards come with 7mm tall rubber feet which help grip the chopping board to most surfaces. The feet can also be micro adjusted if needed by either tightening or loosening the screws.

Surface Grades

In order to provide you with the highest quality end product, our chopping boards are made using the highest quality grade timbers defined as “prime“ in the timber industry. With wood being a natural material even the use of prime grade timber can sometimes (but rarely) contain imperfections. It is not until this material is machined that these are found. While we work around and exclude what we consider structural defects we do have to include some visual defects in order to reduce wasting precious material.

The majority of our chopping boards are single sided and we operate on providing a

‘Grade A’ top surface and a ‘Grade B‘ bottom surface. When glueing a chopping

board we are able to move some imperfections to the bottom leaving the top as ‘clean’ as possible. Our double sided boards incur a small additional cost due to requiring two high quality work surfaces. We work on a ‘Grade A’ top surface and a ‘Grade A2‘ second surface. Grade A2 meaning that it may have a few additional defects in comparison to Grade A, yet less than Grade B.

While we do grade the surfaces we must stress that these defects are few and far

between. In the majority of circumstances you will receive a perfect looking chopping board on both surfaces. Any board that we believe does not live up to these surface grades will fall into our ‘Sale‘ range where the defect is clearly stated.

Please see our product images to see the quality we expect you to receive.

In Stock and Made to Order

Our in stock chopping boards are finished boards ready to ship. These boards are great if you are looking for something ready made and you want to see exactly what you are getting in terms of grain etc.

Made to order chopping boards take approximately 2-3 weeks to hand make to your exact specification before they are shipped to you.

.jpg)

Multiple Design and Style Options

Via our website you can customise size, species, engraving, ranges and styles plus many more attributes. Create a chopping board that is a perfect addition to your kitchen and tailored to how you prepare food.

Engraving & Personalisation

We can personalise any chopping board with an engraving on any side or surface in a variety of fonts.

Juice Grooves

Juice grooves can be added to any of our made to order chopping boards.

Warranty

1 year limited warranty - see our warranty section for more information.

Once a board has made it through a full year in your home it has passed through the winter months where the air tends to be drier due to central heating, which can cause the board to shrink. Then through the summer months where warm air brings higher

humidity this will cause the board to expand. After this one year period any defect

would have become apparent and you can expect with regular maintenance and following our best practices guide that your chopping board will last a long time.

Quality Checks

Before shipping we inspect each chopping board to make sure there are no defects or damage to the board. We also check the levelling of the feet using a surface plate which ensures that the board will not wobble on a flat surface.

If you find that the board wobbles upon arrival it may be sitting on an uneven surface and require the feet adjusting to compensate. With use the wood may move and require that the feet need further adjustment.