Any Pot Plant Stands

One stand to fit all pots*

All of our plant stands can be adjusted to fit different diameter plant pots. This means you no longer need to worry about getting the measuring tape out to make sure your pot is going to fit one of our stands. It's just going to fit!*

We have designed our adjustable stands to accommodate a wide range of common pot sizes. Ranging from small 130mm pots all the way up to the biggest 260mm diameter pots.

Just choose an adjustable plant stand from one of our ranges, then select a height from one of our three sizes. It's as simple as that!

*Fits pots between 130mm to 260mm in diameter.

Adjustable Plant Stands

How do the Plant Stands fit any pot?

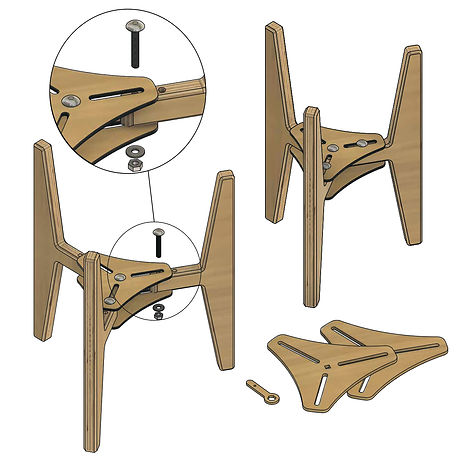

Our plant stands come with two different sized 'plates' which enable the plant stand to adjust to a wide variety of common pot diameters. Each plate enables the three legs to slide in out and can be fixed at at any point making the plant stand perfectly fit to your pot.

The Plates

The small plates suit pots between 130 - 180mm whereas, the larger plates suit pots between 170 - 260mm. When assembling your plant stand use the plates that best fit your pot size.

Turn Me Upside Down!

Our medium and tall plant stands can be turned upside down meaning you can have you plant closer to the ground or higher up using the very same stand!

Your Two Choices

When choosing an Any Pot Plant Stand there are two choices you will need to make, the first being the height of the stand and the second being which range.

Find out all you need to know below.

Plant Stand Heights

We have three heights to choose from when it comes to our plant stands.

Tall, Medium and Short - See below for their individual measurements.

Ranges

Our Any Pot Plant Stands come in a variety of ranges to suit your house and home varying in colours, materials and finishes. The majority of our stands are suited for indoor use only except our new outdoor range which can be kept outside in all weathers.

See us in action!

Want to see how we make, package, assemble and adjust our plant stands?

Then just take a look at our videos below!

FAQ

Here are our most asked questions when it comes to our Z-Chairs.

If we have any further questions please let us know!